Maintaining a home generator is essential to ensure it remains operational and reliable, particularly during unexpected power outages. Whether it’s a standby generator that automatically powers your home during a blackout or a portable unit you crank up manually, each type requires regular attention to keep it in top working order. Proper care involves routine checks and specific procedures to prevent malfunctions and extend the service life of the generator.

Understanding the particulars of your generator’s operation and the safety precautions is critical. Each model and type may have distinct installation needs and operational guidelines. For instance, a portable generator will require different care than a standby model, and it is important to follow the manufacturer’s guidelines for maintenance. Similarly, the fuel used for your generator, safety nuances, and even seasonal changes can affect how you maintain and operate your equipment.

Key Takeaways

- Regular maintenance extends the generator’s lifespan.

- Safety procedures are integral to generator operation.

- Seasonal and fuel considerations impact maintenance.

Understanding Generators

To effectively care for your home generator, it’s critical to grasp the varieties and internal workings of these powerful and essential machines.

Types Of Generators

Generators come in two primary categories: standby and portable. Standby generators are permanently installed and automatically activate during power outages, often running on natural gas or diesel. Conversely, portable generators are mobile units, convenient for various locations, and typically operated with gasoline.

- Standby Generator:

- Fuel: Natural Gas or Diesel

- Automatic operation

- Fixed installation

- Portable Generator:

- Fuel: Gas

- Manual operation

- Mobile use

Generator Components

Several key components are common to both types of generators, each playing a crucial role in functionality:

- Fuel System: The fuel lines ensure a steady flow of fuel to the engine; standby units might connect to home’s natural gas lines.

- Lubrication: Oil is vital for reducing the friction in the engine’s moving parts.

- Air Filtration: The air filter keeps contaminants from entering the engine, necessitating regular checks and replacements.

- Electrical Components: Spark plugs provide the necessary electric spark to ignite the fuel and start combustion.

- Power Generation: The alternator is the component that converts mechanical energy into electrical power.

| Component | Description | Maintenance Notes |

|---|---|---|

| Fuel System | Delivers fuel to the engine; varies by generator type (e.g., natural gas, diesel) | Regular inspection for leaks |

| Oil | Lubricates engine parts | Check levels and replace as needed |

| Air Filter | Prevents debris from entering engine | Clean or replace regularly |

| Spark Plugs | Ignites the fuel in the engine | Check for wear and replace if necessary |

| Alternator | Converts mechanical energy to electrical energy | Inspect for operational integrity |

Understanding these aspects is the foundation for maintaining your generator’s reliability and ensuring its readiness when you need it most.

Generator Maintenance

Maintaining a home generator is essential to ensure it functions effectively when needed. Proper maintenance includes regular checks, swift attention to common issues, and adherence to the manufacturer’s guidelines.

Routine Checks

- Visual Inspection: Periodically examine the unit for any signs of rust, corrosion, or leaks. Ensure that air intake vents are clear of dust and debris to prevent overheating and to maintain adequate ventilation.

- Oil Levels: Regularly check oil levels and look for signs of contamination. An oil change is typically necessary after a certain number of operating hours; consult the owner’s manual for specific intervals.

- Air Filter: Inspect the air filter for cleanliness and replace it according to the schedule suggested in the owner’s manual.

- Fuel System: Check the fuel system for leaks or blockages. Refill fuel as needed, ensuring that you use the type recommended by the manufacturer.

- Battery: Test the battery’s charge and clean the terminals. A well-maintained battery is crucial for reliable generator starting.

Addressing Common Issues

- Perform Regular Maintenance: Set up a maintenance schedule based on the maintenance checks recommended in the owner’s manual.

- Preventive Measures: Regularly apply anti-corrosive treatments to protect metal parts from rust and corrosion.

- Fix Leaks Promptly: If leaks are detected—whether oil, fuel, or coolant—address them immediately to prevent further damage or hazards.

- Keep it Clean: Ensuring the generator is clean affects performance and longevity. Remove any accumulated dust or debris after each use.

Consistent maintenance of a home generator fortifies its readiness and operational durability, helping to provide reliable power when it’s most needed.

Operating A Generator

Operating a generator requires careful attention to starting and stopping protocols, and load management to ensure longevity and safety.

Starting And Stopping

To start a generator, one must first ensure that there is sufficient fuel in the tank, and the oil levels are adequate. It’s crucial to connect extension cords before starting the engine to prevent power surges. For safety, generators should be operated outdoors, away from windows and doors to prevent exposure to carbon monoxide. When the time comes to stop the generator, it’s imperative to disconnect all appliances and let the engine run for a few minutes with no load, allowing it to cool down before powering off.

Load Management

Proper load management is vital when using a generator for emergency power. Overloading a generator can cause damage, so one should know the generator’s wattage capacity and prioritize which appliances to power. Use extension cords rated for the generator’s output, and plug in essential appliances first, such as refrigerators and lights. When refueling, allow the generator to cool down to avoid any hazards. If the generator will not be used for an extended period, it’s advisable to drain fuel from the system or use a fuel stabilizer to maintain it in working order.

Generator Safety

Maintaining safety while operating a home generator is critical to prevent accidents and ensure efficient functioning. This section outlines specific measures focused on preventing carbon monoxide poisoning and adhering to electrical safety practices.

Preventing Carbon Monoxide Poisoning

Carbon monoxide (CO) is a colorless, odorless gas that can be deadly if inhaled. It’s essential to never operate a generator inside homes, garages, basements, or any enclosed space. They should be situated outdoors, at least 20 feet from windows, doors, and vents to prevent CO from entering living spaces. The location of the generator should also consider prevailing winds and ensure that odors and fumes are directed away from the house. For additional safety, always install battery-operated CO detectors in your home.

- Operate generators outdoors in a well-ventilated location.

- Keep generators away from windows, doors, and vents to prevent CO buildup.

- Always have CO detectors installed and functioning in your home.

Electrical Safety Practices

When using a generator, electrical safety is just as important as preventing CO poisoning. Generator owners should keep their generator dry and never use it in the rain or wet conditions to avoid electrocution risks. Make sure to operate it on a dry surface under a structure that provides cover, such as a canopy, while ensuring proper ventilation. The cord length from the generator to appliances should be minimized to prevent voltage drop and overheating, but cords should be long enough to keep the generator a safe distance from the home.

- Keep the generator dry and protected from moisture.

- Connect appliances using heavy-duty, outdoor-rated cords with a wire gauge adequate for the appliance load.

- Use a transfer switch to connect the generator to household wiring, as it prevents backfeeding, which poses a serious risk to utility workers and neighbors.

In conclusion, prioritizing safety during the operation and** maintenance of your home generator** is not negotiable. Following these guidelines will help ensure your generator is a safe and reliable source of power during outages.

Installation And Setup

When installing a home generator, it is crucial to consider both the location of the unit and the complexities of wiring to ensure smooth operation and safety. Careful setup is essential for both standby and portable generators.

Choosing The Right Location

The generator should be placed on a level surface to ensure stable operation. For a standby generator, one needs to choose a location that is close to the electrical service entrance but is also far enough from windows and doors to prevent carbon monoxide poisoning. A portable generator should be easily accessible for operation and refueling, yet far enough away from living areas to reduce noise and fumes. Both types benefit from a shelter or an enclosure to protect them from the elements.

- Standby Generator: 3 feet from home, with good airflow.

- Portable Generator: Stable, well-ventilated area, away from heavy foot traffic.

Generator Wiring

Proper wiring of the generator is critical for safety and compliance with local electrical codes. A transfer switch is an essential component, allowing for safe switching between utility and generator power. For standby generators, the transfer switch should be installed by a certified electrician to ensure that it matches the unit’s capacity and is correctly aligned with home’s electrical system. When using power tools with a portable generator, heavy-duty, outdoor-rated extension cords are recommended to prevent overheating and potential fire hazards.

- Standby Generator: Hire a professional for transfer switch installation.

- Portable Generator: Use appropriate extension cords for power tools.

Portable Generator Care

Proper care of a portable generator involves not only routine maintenance but also attention to how it is transported and stored. Protective measures are equally important to ensure the unit’s longevity and safe operation.

Transportation And Storage

When moving a portable generator, it’s vital to maintain its integrity. A lighter weight unit facilitates easier transportation. It’s essential to ensure the generator is turned off and cooled down before moving it. For storage, a dry, well-ventilated area is preferred to prevent moisture accumulation and rust. Adding a fuel stabilizer to the gasoline can extend the shelf life and protect the engine from corrosion.

Protective Measures

Protective measures for a portable generator include regular maintenance checks and appropriate shielding from environmental elements. Utilizing a generator cover or an enclosure can safeguard the machine from dust and debris when not in use. In operation, the generator must be placed on a flat, stable surface, well away from any flammable materials, to minimize risks of fire or damage.

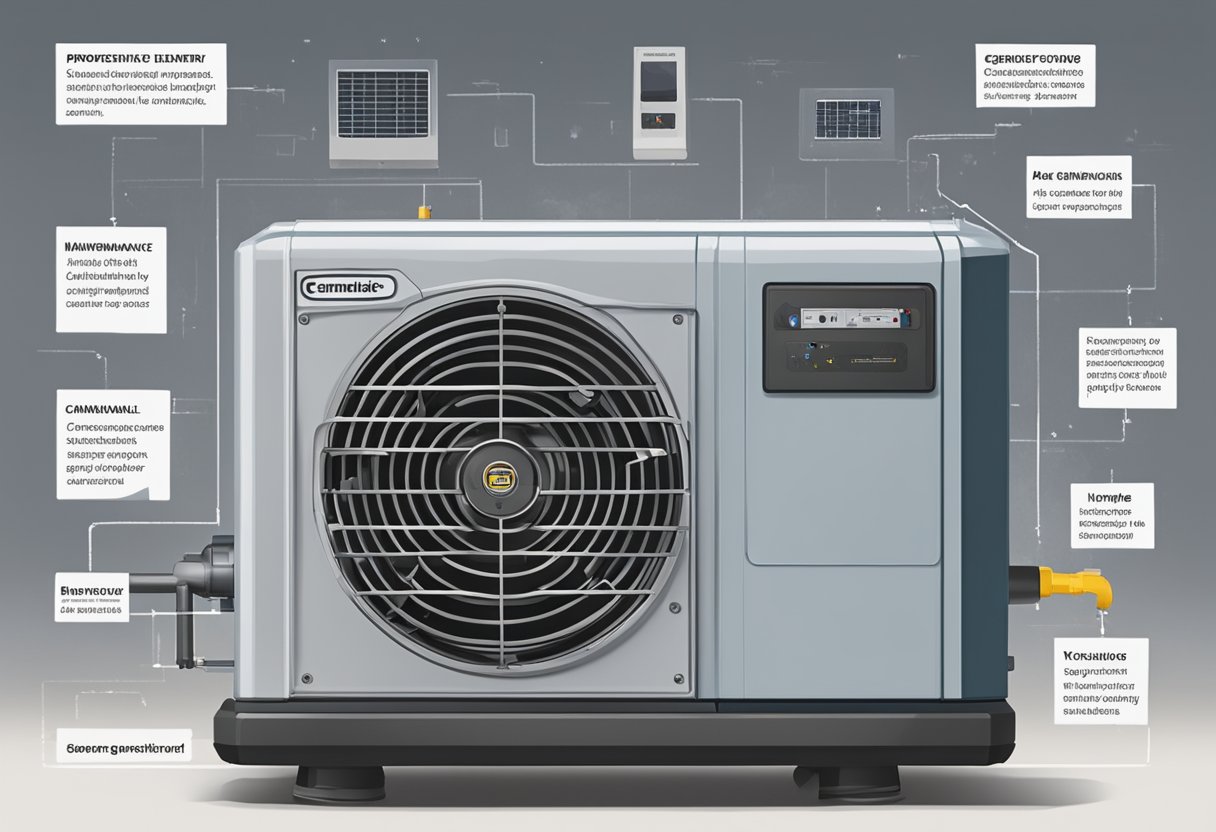

Standby Generator Essentials

A standby generator is a key component in ensuring power continuity during outages. Proper maintenance and understanding the operation of its transfer switch are critical to its reliability and longevity.

Automatic Transfer Switch Importance

The Automatic Transfer Switch (ATS) is integral to a standby generator system. It serves as a critical safety component by ensuring that the generator’s power does not backfeed into the grid, which can cause injuries to utility workers or damage to the electrical system. When utility power fails, the ATS automatically activates the standby generator, thus maintaining an uninterrupted power supply to the home. It’s essential that the ATS be properly configured and regularly inspected to ensure efficient operation.

Standby Generator Upkeep

Regular upkeep is crucial for standby generators to function effectively. Owners should monitor fuel levels and add a fuel stabilizer to prevent degradation if the generator is not used for extended periods. Oil levels and quality are vital; they should be checked monthly and changed according to the manufacturer’s guidelines, as clean oil is essential for engine health. Additionally, the coolant should be inspected to prevent the engine from overheating. Standby generators should be run periodically to ensure they’re in working order and to identify any potential issues before an emergency arises.

A well-maintained generator is always ready for the next power outage, providing peace of mind and comfort. It is imperative to follow the manufacturer’s maintenance schedule for optimal performance.

Seasonal Considerations

Maintaining a home generator requires attention to seasonal challenges to ensure its reliability when it’s needed most. Precise preparation can prevent issues like battery failure, spark plug deterioration, and overheating during extreme weather conditions.

Preparing For Winter

Winter storms can cause extended power outages, making a well-maintained generator crucial. Prior to the cold season:

- Spark Plugs: Ensure they are clean and properly gapped to prevent starting issues in cold weather.

- Battery: Check the battery’s charge and terminals because cold temperatures can reduce its effectiveness.

- Coolant: Verify that the coolant level is adequate and the antifreeze concentration is suitable for your local winter temperatures to avoid freezing.

Generators should also be located where they can be easily accessed even during a heavy winter storm, away from accumulations of snow and ice that can impair function and pose safety hazards.

Summer Outages

During hot summer months, generators face the risk of:

- Overheating: Ensure good airflow around the unit; remove any debris and check the cooling system to prevent overheating during prolonged use.

- Severe Weather: Secure the generator and protect it against potential flood damage, as summer often brings severe weather that can disrupt power.

To combat summer power disruptions, performing regular maintenance checks is imperative. This includes inspecting the generator’s exterior for any signs of wear that might lead to inefficiency or failure during a summer outage.

Fuel Types And Choices

When selecting a fuel type for a home generator, one must consider the availability, cost, and storage requirements of the fuel. These factors can greatly influence the generator’s performance and maintenance needs over time.

Gasoline Versus Propane Generators

Gasoline is a widely available fuel, but it has a shorter shelf life and requires the use of a fuel stabilizer to remain viable for emergency use. Gasoline engines are generally more common and can be easier to maintain. However, propane, being less volatile, offers a longer shelf life and cleaner burning. Generators using propane can store fuel for longer periods without degradation, which is a decisive factor for infrequent use.

Key points for Gasoline generators:

- Requires fuel stabilizer for long-term storage

- More common and familiar maintenance

Key points for Propane generators:

- Cleaner burning and less maintenance

- Longer shelf life without fuel stabilizer

Evaluating Fuel Storage

When evaluating storage options, safety and longevity are paramount. Natural Gas and Diesel are options for those seeking fewer refueling requirements due to their ability to tap into existing supply lines (natural gas) or store large quantities safely (diesel). Diesel, in particular, is less flammable and, as mentioned in How to Choose the Right Fuel for Your Generator, can be easier to maintain due to the engine’s durability and lack of spark plugs.

Fuel Oil and Gasoline require secure, airtight containers and should be used within a year, even with stabilizers. Propane, conversely, can be stored indefinitely, making it a practical choice for low-maintenance readiness.

Considerations for Fuel Storage:

- Natural Gas: Connects to home supply; no refueling

- Diesel: Stable and stores well; requires attention to safe containment

- Propane: Indefinite shelf life; needs appropriate pressurized containers

- Gasoline/Fuel Oil: Short shelf life; best for frequent use or with stabilizers

By understanding each fuel type’s characteristics and storage requirements, homeowners can make informed decisions to ensure their generators remain ready and reliable for when they are most needed.

Troubleshooting

In ensuring the reliability of your home generator, understanding how to diagnose and troubleshoot common issues is vital. This section will guide you through identifying typical problems and performing routine checks to keep your generator in peak condition.

Common Generator Problems

Several issues can hinder the operation of a generator. It’s crucial to check the following components if your generator fails to start or isn’t performing as expected:

- Oil Levels: Insufficient oil can lead to engine damage. Ensure the oil level is within the recommended range.

- Fuel Filter: A clogged fuel filter restricts fuel flow. Replace it if it’s dirty or has been in use for an extensive period.

- Air Filter: Like the fuel filter, a dirty air filter can impair engine performance. Inspecting and cleaning or replacing the air filter regularly is recommended.

When a generator runs but fails to deliver power, verify the condition of each receptacle and look for systemic issues such as a tripped circuit breaker or a malfunctioning GFCI.

Maintenance-Related Issues

Maintenance is preventative, so regular checks should be a priority to avoid operational problems.

- Coolant Level: Check that the coolant is at the correct level to prevent the engine from overheating.

- Leaks: Oil, fuel, or coolant leaks can cause significant problems. Regular inspections help in early detection and prevent potential hazards like carbon monoxide poisoning.

- Carburetor: Over time, the carburetor may get clogged especially with stale fuel. Cleaning it periodically ensures proper engine performance.

Remember, always remove the spark plug wire before performing any maintenance to ensure safety. Follow the user manual’s troubleshooting guide for specific guidance relating to your generator model.

Conclusion

Regular maintenance is the backbone of a reliable home generator. They underscore the difference between peace of mind and unexpected blackout frustrations. Proper care for a generator involves routine checks and diligent cleaning. One must ensure the air flow vents are clear of obstruction for optimal performance—it’s a simple step that makes a significant difference.

A home generator stands between one’s comfort and potential outages, so keeping up with fuel levels and ensuring timely oil changes are paramount. Running your generator briefly each month keeps it in working order and ready to supply backup power when the need arises.

In the realm of emergency power generators, neglect can lead to failure. Therefore, it is essential to not only follow the manufacturer’s instructions but also to keep a log of all maintenance activities. This includes noting the replacement of air filters after every 100 hours of operation, or more frequently if required.

Ultimately, the longevity and efficiency of your home generator hinge on the commitment to regular upkeep. Adhering to a maintenance schedule ensures that your generator is prepared to offer uninterrupted power, providing emergency power when external sources fail. It is this dedication to proactive care that secures an enduring source of backup power.

Frequently Asked Questions

Routine maintenance is crucial for ensuring your home generator operates efficiently and reliably. Understanding the nuances of generator care ensures preparedness for when power is most needed.

What is the recommended maintenance schedule for a home generator?

Home generators should undergo a comprehensive check every six months or after 100 hours of use, whichever comes first. A thorough inspection includes checking fluid levels, battery condition, and filter replacement.

How often should oil be changed in a residential generator, and does it vary by type?

Oil in a residential generator should typically be changed every 100 hours of operation or once per year. The frequency may vary depending on the generator type; standby generators may have different requirements than portable models.

What are the steps to ensure my portable generator operates reliably during an emergency?

To ensure reliable operation, regularly run the generator, maintain proper oil and fuel levels, use fresh fuel with a stabilizer, and store the unit in a clean and dry area. A maintenance checklist for portable generators can guide through the necessary steps.

What procedures should be followed to properly maintain a generator during prolonged periods of non-use?

During prolonged periods of non-use, run the generator periodically to charge the battery, use fuel stabilizer to prevent stale fuel, change the oil, and protect the unit from moisture and dust.

Can you outline a basic generator maintenance checklist for homeowners?

A basic maintenance checklist should include: visual inspection for leaks and damage, checking and replacing oil and filters as needed, testing battery and cleaning terminals, and ensuring the area around the generator is clear of debris. For detailed information, homeowners can refer to guides on generator maintenance tips.

What are the typical costs associated with professional whole house generator maintenance?

Professional whole house generator maintenance costs vary, generally ranging from $200 to $500 per visit. The price includes a thorough inspection, oil and filter change, and testing of all generator functions.