The world of glues encompasses a vast array of adhesives designed to cater to diverse materials and applications. From woodworking and crafting to household repairs and DIY projects, having the right glue at hand can make a significant difference in the success of a task. Understanding the unique properties and ideal uses of different types of glues is essential for making informed decisions when selecting the best adhesive for a specific project.

Various factors come into play when choosing the most suitable glue, including the materials being bonded, the intended application, and environmental conditions. Whether it’s wood, plastic, fabric, metal, or a combination of materials, each type of glue offers distinct advantages and considerations. For woodworking projects, the emphasis is on strong bonding strength and compatibility with different wood types, while plastic bonding requires adhesives that can create durable bonds without causing damage. Fabric glues need to offer flexibility and washability, and metal bonding adhesives should possess high heat resistance and exceptional strength.

In addition to material-specific glues, there are all-purpose and waterproof variants that cater to a wide range of applications. All-purpose glues offer versatility and convenience, while waterproof glues are essential for outdoor or water-exposed projects. Craft glues are tailored to the specific demands of crafting endeavors, and DIY projects often benefit from reliable and easy-to-use adhesives. Understanding the unique attributes of each type of glue allows individuals to make informed decisions based on their specific needs and project requirements.

As such, this comprehensive guide aims to provide valuable insights into the best glues available for various materials and applications, offering recommendations and tips for proper glue application. By navigating through the world of glues and understanding the factors to consider, individuals can confidently select the most appropriate adhesive for their projects, ensuring strong and durable bonds for their diverse endeavors.

Understanding Different Types of Glues

When it comes to understanding the different types of glues, it’s essential to recognize that not all adhesives are created equal. Each type of glue possesses unique properties, bonding capabilities, and ideal uses, making it crucial to have a comprehensive understanding of the diverse range of glues available in the market. From super glues and epoxy adhesives to craft glues and waterproof variants, each type serves specific purposes and caters to distinct materials and applications.

Super Glues (Cyanoacrylate Adhesives)

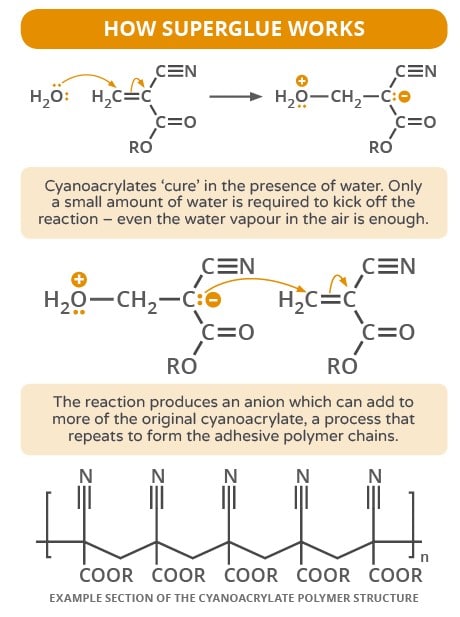

Super glues, also known as cyanoacrylate adhesives, are renowned for their fast-acting and strong bonding properties. These adhesives create nearly instantaneous bonds when exposed to moisture, making them ideal for quick fixes and applications that require rapid adhesion. Super glues are suitable for bonding materials such as metal, plastic, rubber, and ceramics. However, they may not be the best choice for applications requiring flexibility or with porous surfaces.

Epoxy Adhesives

Epoxy adhesives are two-part adhesives consisting of a resin and a hardener that must be mixed before application. Once mixed, epoxy adhesives offer exceptional bonding strength, high heat resistance, and durability. They are well-suited for bonding materials such as metal, wood, glass, and ceramics. Epoxy adhesives are versatile and can be used for various applications, including repairs, construction, and crafting.

Craft Glues

Craft glues are specifically formulated for use in crafting and artistic endeavors. These adhesives offer features such as extended open time, flexibility, and compatibility with a wide range of craft materials. Craft glues are ideal for bonding materials such as paper, fabric, foam, and embellishments. They provide a reliable and durable bond while allowing for adjustments during the crafting process.

Waterproof Glues

Waterproof glues are designed to withstand exposure to moisture and are suitable for outdoor or water-exposed applications. These adhesives offer resistance to water, humidity, and varying temperatures, making them ideal for bonding materials in damp or wet conditions. Waterproof glues are commonly used for outdoor furniture repairs, marine applications, and other projects requiring water-resistant bonding.

All-Purpose Glues

All-purpose glues are versatile adhesives that can bond a wide variety of materials, making them suitable for general household repairs and DIY projects. These glues offer convenience and ease of use, allowing individuals to tackle multiple tasks with a single adhesive. All-purpose glues are often used for bonding materials such as wood, metal, plastic, fabric, and more.

Factors to Consider When Choosing a Glue

When choosing a glue for a particular project, several critical factors should be taken into consideration to ensure optimal bonding performance and long-term durability. Understanding these factors can help individuals make informed decisions and select the most suitable adhesive for their specific needs and applications.

Materials Being Bonded

One of the primary factors to consider when choosing a glue is the type of materials being bonded. Different adhesives are formulated to bond specific materials effectively. For instance, wood glues are designed to work well with wood surfaces, while plastic glues are formulated to create durable bonds on plastic materials. It’s essential to select a glue that is compatible with the specific materials involved in the project to achieve a strong and lasting bond.

Intended Application

The intended application of the adhesive is another crucial factor to consider. Whether the project involves indoor or outdoor use, exposure to moisture, high temperatures, or varying environmental conditions, the adhesive selected should be suitable for the intended application. For example, outdoor projects may require a waterproof adhesive that can withstand exposure to the elements, while indoor craft projects may benefit from a flexible and fast-drying adhesive.

Bonding Strength and Durability

The bonding strength and durability of the adhesive are essential considerations, particularly for projects that require long-lasting and reliable bonds. Different adhesives offer varying levels of bonding strength, ranging from instant bonds for quick fixes to high-strength bonds for heavy-duty applications. Understanding the bonding strength and durability of the adhesive is crucial for ensuring that it can withstand the demands of the project.

Open Time and Curing Period

Open time refers to the amount of time the adhesive remains workable after application, while the curing period is the time required for the adhesive to reach its full bonding strength. These factors are important for projects that involve intricate assembly or adjustments during the bonding process. Adhesives with longer open times provide more flexibility for positioning and adjusting the bonded materials, while fast-curing adhesives offer quick bonding solutions.

Environmental Considerations

Environmental factors such as temperature, humidity, and exposure to UV radiation can impact the performance of adhesives. It’s essential to select an adhesive that can withstand the specific environmental conditions to which the bonded materials will be exposed. For example, outdoor applications may require adhesives with UV resistance and weatherproof properties to ensure long-term durability.

By considering these factors when choosing a glue, individuals can make informed decisions and select the most appropriate adhesive for their specific projects. Taking into account the materials being bonded, the intended application, bonding strength, open time, curing period, and environmental considerations can help ensure successful bonding and optimal results for a wide range of applications.

Best Glues for Wood

When it comes to woodworking projects, selecting the best glue is crucial for achieving strong and durable bonds between wood components. Different types of wood glues offer varying properties and advantages, making it essential to choose the most suitable adhesive for specific woodworking applications.

PVA Wood Glue

Polyvinyl acetate (PVA) wood glue, also known as carpenter’s glue, is a popular choice for woodworking projects due to its versatility and ease of use. PVA wood glue is available in both yellow and white variants, with the yellow type offering water resistance. It provides a strong bond, dries clear, and is suitable for a wide range of wood types. PVA wood glue is ideal for general woodworking, joinery, and furniture assembly.

Polyurethane Wood Glue

Polyurethane wood glue is known for its exceptional bonding strength and resistance to water, heat, and solvents. This type of wood glue expands as it cures, filling gaps and creating a strong bond. Polyurethane wood glue is suitable for outdoor woodworking projects, laminating, and joining hardwoods.

Epoxy Wood Glue

Epoxy wood glue is a two-part adhesive that consists of a resin and a hardener. It offers high bonding strength, excellent gap-filling properties, and exceptional durability. Epoxy wood glue is suitable for bonding different wood species, including hardwoods and softwoods. It is also ideal for applications that require heat and water resistance, such as boat building and marine woodworking projects.

Cyanoacrylate (CA) Wood Glue

Cyanoacrylate wood glue, commonly known as super glue, is valued for its fast-acting bonding properties. While it may not be the primary choice for large woodworking projects, cyanoacrylate wood glue is useful for small repairs, intricate wood joinery, and bonding non-porous wood materials. It provides rapid adhesion and can be particularly effective for woodturning and wood crafting applications.

Best Glues for Plastic

Selecting the best wood glue for a specific woodworking project involves considering factors such as bonding strength, water resistance, gap-filling capabilities, and the specific requirements of the project. By understanding the properties and ideal uses of different wood glues, individuals can confidently choose the most appropriate adhesive to achieve strong and reliable bonds in their woodworking endeavors.

When it comes to bonding plastic materials, selecting the right adhesive is essential for achieving durable and reliable bonds. Different types of glues are formulated to work effectively with various types of plastics, offering specific properties and advantages for different applications.

Cyanoacrylate (Super Glue)

Cyanoacrylate adhesives, commonly known as super glues, are popular for bonding plastic materials due to their fast-acting and strong bonding properties. Super glues create rapid bonds and are suitable for bonding non-porous plastics such as acrylic, polycarbonate, and ABS. They are ideal for small plastic repairs, model making, and other applications that require quick adhesion.

Epoxy Adhesives

Epoxy adhesives are versatile and can be effective for bonding a wide range of plastics, including rigid and flexible plastics. These adhesives offer high bonding strength, excellent gap-filling properties, and resistance to heat and chemicals. Epoxy adhesives are suitable for bonding plastic components in various applications, such as automotive repairs, household items, and DIY projects.

Polyurethane Adhesives

Polyurethane adhesives are known for their flexibility, durability, and resistance to impact and vibration. They can effectively bond a variety of plastics, including polyethylene and polypropylene, which are typically challenging to bond due to their low surface energy. Polyurethane adhesives are suitable for plastic assemblies that require strong and resilient bonds.

Solvent Cement

Solvent cement, also known as plastic welding adhesive, is specifically designed for bonding thermoplastic materials such as PVC, CPVC, and ABS. This type of adhesive chemically softens the plastic surfaces, allowing them to fuse together when the solvent evaporates. Solvent cement is commonly used in plumbing, construction, and fabrication of plastic components.

Specialized Plastic Adhesives

Certain specialized adhesives are formulated for bonding specific types of plastics, such as polypropylene and polyethylene. These adhesives are designed to address the challenges associated with bonding low surface energy plastics, providing strong and durable bonds for these materials.

Selecting the best glue for plastic involves considering factors such as the type of plastic, bonding strength, flexibility, and environmental resistance. By understanding the properties and ideal uses of different plastic adhesives, individuals can confidently choose the most appropriate adhesive to achieve strong and durable bonds in their plastic bonding applications.

Best Glues for Fabric

When it comes to bonding fabric materials, choosing the right adhesive is essential for achieving durable and flexible bonds without causing damage to the fabric. Different types of fabric glues offer specific properties and advantages for various fabric bonding applications, catering to different materials and usage scenarios.

Fabric Glue

Fabric glue, also known as fabric adhesive, is specifically formulated for bonding fabric materials without the need for sewing. This type of glue is designed to provide a flexible and washable bond, making it suitable for fabric repairs, hemming, and crafting projects. Fabric glue is often used for bonding fabrics such as cotton, denim, felt, and polyester, offering a convenient alternative to traditional sewing methods.

Spray Adhesive

Spray adhesives are versatile and can be used for bonding fabric materials in various applications. They offer ease of application and provide a temporary or repositionable bond, making them suitable for fabric positioning, quilting, and upholstery projects. Spray adhesives are available in different formulations, including repositionable and permanent options, allowing for flexibility in fabric bonding applications.

Hot Melt Glue

Hot melt glue, commonly used in glue guns, can be effective for bonding fabric materials when used with care. It offers a strong and quick bond, making it suitable for fabric embellishments, costume design, and crafting projects. Hot melt glue provides a durable bond on fabrics such as felt, ribbon, and lightweight textiles, offering a convenient and efficient bonding solution.

Fusible Web

Fusible web, also known as fusible adhesive, is a fabric bonding material that is activated by heat. It is commonly used in appliqué, patchwork, and fabric bonding applications. Fusible web provides a strong bond when activated with an iron, allowing for seamless fabric bonding without the need for sewing. It is suitable for a wide range of fabric types and can be used for both temporary and permanent fabric bonding.

Liquid Stitch

Liquid stitch is a fabric adhesive that offers a flexible and permanent bond, making it suitable for fabric repairs, alterations, and crafting projects. It provides a no-sew solution for fabric bonding and can be used on various fabric materials, including cotton, polyester, and blends. Liquid stitch offers a convenient and durable bonding solution for fabric applications.

Selecting the best glue for fabric involves considering factors such as bond flexibility, washability, ease of application, and specific fabric bonding requirements. By understanding the properties and ideal uses of different fabric adhesives, individuals can confidently choose the most appropriate adhesive to achieve strong and flexible bonds in their fabric bonding applications.

Best Glues for Metal

When it comes to bonding metal components, choosing the right adhesive is crucial for achieving strong and durable bonds that can withstand the demands of various applications. Different types of metal glues offer specific properties and advantages for bonding metal materials, catering to different metal types and usage scenarios.

Epoxy Adhesives

Epoxy adhesives are known for their exceptional bonding strength and durability, making them suitable for bonding metal components. These adhesives offer high heat resistance and excellent gap-filling properties, providing strong and long-lasting bonds for metal assemblies. Epoxy adhesives are versatile and can be used for various metal bonding applications, including automotive repairs, metal fabrication, and industrial assembly.

Cyanoacrylate (Super Glue)

Cyanoacrylate adhesives, commonly known as super glues, are valued for their fast-acting bonding properties and can be effective for bonding metal components. Super glues create rapid bonds and are suitable for small metal repairs, model making, and other applications that require quick adhesion. They provide strong and reliable bonds for metal materials such as aluminum, steel, and copper.

Metal Epoxy Putty

Metal epoxy putty, also known as metal-filled epoxy, is a specialized adhesive designed for bonding metal surfaces and filling gaps in metal components. This type of adhesive offers excellent adhesion to metal substrates and can be used for repairing metal parts, sealing leaks, and creating strong bonds in metal assemblies. Metal epoxy putty provides a durable and resilient bond for various metal bonding applications.

Polyurethane Adhesives

Polyurethane adhesives are known for their flexibility, durability, and resistance to impact and vibration, making them suitable for bonding metal components that are subject to movement and stress. These adhesives provide strong and resilient bonds for metal assemblies, including structural bonding, metal fabrication, and industrial applications.

Metal Welding Adhesives

Specialized metal welding adhesives are designed to create strong and durable bonds between metal surfaces, simulating the strength and integrity of welded joints. These adhesives offer high tensile strength and can be used for bonding metal components in various applications, including metalworking, construction, and repair.

Selecting the best glue for metal involves considering factors such as bonding strength, heat resistance, gap-filling capabilities, and the specific requirements of the metal bonding application. By understanding the properties and ideal uses of different metal adhesives, individuals can confidently choose the most appropriate adhesive to achieve strong and durable bonds in their metal bonding applications.

Best All-Purpose Glues

All-purpose glues are versatile adhesives that offer convenience and ease of use for a wide range of bonding applications. These adhesives are designed to bond various materials, making them suitable for general household repairs, crafting projects, DIY endeavors, and more. Different types of all-purpose glues offer specific properties and advantages, catering to diverse bonding needs and usage scenarios.

Multi-Surface Adhesives

Multi-surface all-purpose adhesives are formulated to bond a variety of materials, including wood, metal, plastic, fabric, and more. These adhesives offer strong and reliable bonds for different surfaces, providing versatility and convenience for various projects. Multi-surface all-purpose glues are suitable for general household repairs, DIY projects, and crafting applications.

Quick-Drying All-Purpose Glues

Quick-drying all-purpose glues provide rapid adhesion and are ideal for applications that require fast bonding solutions. These adhesives offer convenience and efficiency, allowing for quick repairs and assembly of various materials. Quick-drying all-purpose glues are commonly used for small fixes, crafting projects, and quick bonding needs.

All-Weather Adhesives

All-weather all-purpose glues are designed to withstand exposure to varying environmental conditions, including moisture, temperature fluctuations, and UV radiation. These adhesives offer weatherproof properties, making them suitable for outdoor repairs, construction projects, and applications that require resistance to the elements. All-weather all-purpose glues provide durable and resilient bonds in challenging environmental conditions.

Flexible All-Purpose Glues

Flexible all-purpose glues offer flexibility and resilience, making them suitable for applications that involve movement, vibration, or stress. These adhesives provide strong and durable bonds that can withstand dynamic conditions, making them ideal for bonding materials subject to frequent use or mechanical stress. Flexible all-purpose glues are commonly used in automotive repairs, household applications, and crafting projects.

Selecting the best all-purpose glue involves considering factors such as bonding versatility, drying time, weather resistance, flexibility, and specific bonding requirements. By understanding the properties and ideal uses of different all-purpose glues, individuals can confidently choose the most appropriate adhesive to achieve strong and reliable bonds for a wide range of applications.

Best Waterproof Glues

Waterproof glues are specifically formulated to create strong and durable bonds that can withstand exposure to moisture, humidity, and water. These adhesives offer resistance to water, making them suitable for outdoor applications, marine projects, and bonding materials in damp or wet conditions. Different types of waterproof glues provide specific properties and advantages, catering to diverse bonding needs and usage scenarios.

Marine Adhesives

Marine-grade waterproof adhesives are designed for applications in marine environments, offering resistance to saltwater, moisture, and UV radiation. These adhesives provide strong and durable bonds for boat repairs, marine construction, and nautical applications. Marine adhesives offer exceptional weatherproof properties and are suitable for bonding materials exposed to harsh marine conditions.

Outdoor Waterproof Glues

Outdoor waterproof glues are formulated to withstand exposure to the elements, including rain, sunlight, and temperature fluctuations. These adhesives offer weatherproof properties and are suitable for outdoor repairs, construction projects, and applications in outdoor settings. Outdoor waterproof glues provide durable and resilient bonds for materials in outdoor environments.

Moisture-Resistant Adhesives

Moisture-resistant waterproof glues offer resistance to moisture and humidity, making them suitable for applications in damp or humid conditions. These adhesives provide strong and reliable bonds for materials in indoor environments with high humidity levels, such as bathrooms, kitchens, and utility areas. Moisture-resistant waterproof glues offer durability and resilience in moist conditions.

Submersible Adhesives

Submersible waterproof glues are designed to create bonds that can withstand submersion in water. These adhesives offer exceptional water resistance and are suitable for applications that involve constant or intermittent contact with water. Submersible waterproof glues provide durable and resilient bonds for underwater repairs, aquatic projects, and water-related applications.

Selecting the best waterproof glue involves considering factors such as water resistance, weatherproof properties, moisture resistance, and specific bonding requirements. By understanding the properties and ideal uses of different waterproof glues, individuals can confidently choose the most appropriate adhesive to achieve strong and reliable bonds for applications exposed to moisture and water.

Best Craft Glues

Craft glues are essential for a wide range of crafting and artistic endeavors, offering specific properties and advantages for bonding various materials commonly used in crafting projects. These adhesives provide flexibility, ease of use, and reliable bonding capabilities, catering to the specific demands of crafting applications.

Paper and Card Adhesives

Craft glues formulated for paper and card materials offer a safe and effective bonding solution for scrapbooking, card making, and paper crafting projects. These adhesives provide a strong and durable bond for paper and cardstock, allowing for precise and clean application without causing damage to delicate materials.

Embellishment Adhesives

Embellishment adhesives are designed for bonding decorative elements such as beads, sequins, rhinestones, and embellishments. These adhesives offer precision and control, allowing for secure and long-lasting attachment of embellishments to various crafting surfaces. Embellishment adhesives provide a reliable bonding solution for intricate and detailed crafting projects.

Fabric Adhesives

Craft glues formulated for fabric materials offer flexibility and washability, making them suitable for fabric-based crafting projects. These adhesives provide a strong and durable bond for fabric embellishments, appliqué, and fabric crafting applications. Fabric adhesives allow for seamless and reliable bonding of fabric materials without the need for sewing.

Wood and Mixed Media Adhesives

Craft glues suitable for wood and mixed media applications provide versatility and bonding strength for woodworking, mixed media art, and three-dimensional crafting projects. These adhesives offer strong and durable bonds for wood, mixed media elements, and various crafting materials, providing a reliable solution for diverse crafting applications.

Specialty Crafting Adhesives

Certain specialty crafting adhesives are formulated for specific crafting applications, such as decoupage, quilling, and polymer clay bonding. These adhesives offer unique properties tailored to the specific demands of specialized crafting techniques, providing a reliable and effective bonding solution for niche crafting projects.

Selecting the best craft glue involves considering factors such as material compatibility, bonding strength, precision, and specific crafting requirements. By understanding the properties and ideal uses of different craft glues, individuals can confidently choose the most appropriate adhesive to achieve strong and reliable bonds for their diverse crafting and artistic endeavors.

Best Glues for DIY Projects

When it comes to DIY projects, having the right adhesive at hand is essential for tackling a wide range of tasks effectively. Different types of glues offer specific properties and advantages for DIY endeavors, providing versatility, ease of use, and reliable bonding capabilities for various materials and applications commonly encountered in DIY projects.

All-Purpose Adhesives

All-purpose glues are versatile and can be effectively used for a wide range of DIY projects, offering convenience and ease of use. These adhesives provide strong and reliable bonds for bonding materials such as wood, metal, plastic, fabric, and more. All-purpose glues are suitable for general repairs, household projects, and DIY crafting applications, offering a convenient and efficient bonding solution for diverse DIY tasks.

Woodworking Adhesives

For woodworking projects, selecting the right wood glue is crucial for achieving strong and durable bonds between wood components. Different types of wood glues, such as PVA wood glue, epoxy adhesives, and polyurethane adhesives, offer specific properties tailored to woodworking applications, providing versatility and bonding strength for DIY woodworking projects.

Super Glues

Cyanoacrylate adhesives, commonly known as super glues, are valued for their fast-acting bonding properties, making them suitable for small repairs, model making, and intricate DIY projects. These adhesives provide rapid adhesion and strong bonds for a variety of materials commonly encountered in DIY tasks, offering a quick and effective bonding solution for small-scale projects.

Multi-Surface Adhesives

Multi-surface all-purpose adhesives are formulated to bond a variety of materials, providing versatility and convenience for DIY projects involving diverse materials. These adhesives offer strong and reliable bonds for different surfaces, allowing for seamless assembly and repairs in various DIY applications.

Specialized DIY Adhesives

Certain specialized adhesives are tailored to specific DIY applications, such as construction adhesives for building and home improvement projects, tile adhesives for tiling applications, and sealants for caulking and sealing tasks. These adhesives offer specific properties and advantages for addressing the unique demands of specialized DIY tasks, providing reliable and effective bonding solutions for niche DIY applications.

Selecting the best glue for DIY projects involves considering factors such as material compatibility, bonding strength, versatility, and specific DIY requirements. By understanding the properties and ideal uses of different DIY adhesives, individuals can confidently choose the most appropriate adhesive to achieve strong and reliable bonds for their diverse DIY endeavors.

Best Glues for Outdoor Use

When it comes to outdoor use, selecting the right adhesive is crucial for ensuring strong and durable bonds that can withstand exposure to the elements. Different types of glues offer specific properties and advantages for outdoor applications, providing weatherproof, water-resistant, and UV-resistant bonding solutions for various materials commonly encountered in outdoor projects.

Weatherproof Adhesives

Weatherproof adhesives are designed to withstand exposure to outdoor conditions, including rain, sunlight, and temperature fluctuations. These adhesives offer resistance to weathering and provide strong and durable bonds for outdoor repairs, construction projects, and applications in outdoor settings. Weatherproof adhesives are suitable for bonding materials such as wood, metal, plastic, and more in outdoor environments.

Marine Adhesives

Marine-grade waterproof adhesives are specifically formulated for applications in marine environments, offering resistance to saltwater, moisture, and UV radiation. These adhesives provide strong and durable bonds for boat repairs, marine construction, and nautical applications, making them suitable for outdoor use in marine settings.

Outdoor Wood Adhesives

For outdoor woodworking projects, selecting the right wood glue is essential for achieving durable bonds that can withstand exposure to the elements. Weatherproof wood glues offer resistance to moisture and weathering, providing strong and reliable bonds for outdoor furniture, decking, and other wood applications in outdoor environments.

UV-Resistant Adhesives

UV-resistant adhesives are designed to withstand exposure to sunlight and provide resistance to UV degradation. These adhesives offer durability and resilience in outdoor applications where materials are exposed to direct sunlight, making them suitable for bonding materials in outdoor settings.

All-Weather Adhesives

All-weather adhesives are formulated to withstand exposure to varying environmental conditions, including moisture, temperature fluctuations, and UV radiation. These adhesives offer resistance to the elements and provide strong and durable bonds for outdoor repairs, construction projects, and applications in challenging outdoor environments.

Selecting the best glue for outdoor use involves considering factors such as weather resistance, UV resistance, moisture resistance, and specific outdoor bonding requirements. By understanding the properties and ideal uses of different outdoor adhesives, individuals can confidently choose the most appropriate adhesive to achieve strong and reliable bonds for their diverse outdoor projects.

Tips for Proper Glue Application

Proper glue application is essential for achieving strong and durable bonds in various projects. By following these tips, individuals can ensure effective adhesive application and optimize the bonding performance of different types of glues for a wide range of materials and applications.

Surface Preparation

Before applying the glue, it is crucial to prepare the surfaces to be bonded. Clean the surfaces thoroughly to remove any dirt, grease, or debris that could hinder bonding. For non-porous materials, such as metal or plastic, roughening the surface with sandpaper can improve adhesion. In woodworking, ensuring that the surfaces fit tightly together without gaps is key to achieving a strong bond.

Appropriate Amount of Glue

Applying the appropriate amount of glue is essential for achieving optimal bonding. Too little glue may result in a weak bond, while excess glue can lead to messiness and squeeze-out. Follow the manufacturer’s recommendations regarding the proper amount of glue to use for the specific materials and application.

Even Distribution

When applying the glue, strive for an even distribution across the bonding surfaces. This helps ensure that the adhesive makes full contact with the materials being bonded, promoting a strong and uniform bond. Use a brush, roller, or spreader to evenly distribute the glue, especially for large surface areas.

Clamping and Pressure

Applying clamping pressure is often necessary to achieve a strong bond. Utilize clamps or other suitable methods to hold the bonded materials firmly together while the glue cures. The application of pressure helps to ensure intimate contact between the mating surfaces, promoting effective bonding.

Drying and Curing Time

Allow the glued materials to dry and cure according to the manufacturer’s instructions. It is important to provide adequate time for the adhesive to set and reach its full bonding strength. Rushing the drying or curing process can compromise the integrity of the bond.

Environmental Considerations

Consider the environmental conditions during glue application and curing. Temperature, humidity, and ventilation can impact the performance of certain adhesives. Adhere to the recommended environmental conditions specified by the adhesive manufacturer for optimal bonding results.

By following these tips for proper glue application, individuals can enhance the bonding performance of various adhesives and achieve strong and durable bonds in their diverse projects, whether it’s woodworking, crafting, repairs, or DIY endeavors.

Common Mistakes to Avoid When Using Glues

When using glues for various projects, it’s important to be mindful of common mistakes that can compromise the effectiveness of the adhesive and the quality of the bond. By avoiding these common errors, individuals can enhance the bonding performance of different types of glues and achieve strong and durable bonds in their projects.

Insufficient Surface Preparation

One of the common mistakes when using glues is inadequate surface preparation. Failing to clean and prepare the bonding surfaces properly can result in poor adhesion. Surfaces should be free of dirt, grease, and other contaminants to ensure optimal bonding.

Overuse of Glue

Using an excessive amount of glue is a common mistake that can lead to messy applications, squeeze-out, and weak bonds. Following the manufacturer’s recommended guidelines for the proper amount of glue to use is essential for achieving effective bonding without wastage.

Uneven Glue Application

Uneven distribution of glue can lead to inconsistent bonding and weak spots. It’s important to apply the adhesive evenly across the bonding surfaces to ensure that the glue makes full contact with the materials being bonded.

Improper Clamping or Pressure

Inadequate clamping or pressure during the curing process is a common mistake that can compromise the integrity of the bond. Proper clamping or applying the recommended pressure is essential for achieving strong and uniform bonds.

Rushing the Drying or Curing Process

Rushing the drying or curing process can result in premature handling of the bonded materials, leading to weak bonds. It’s important to allow the adhesive to dry and cure according to the manufacturer’s instructions to ensure optimal bonding strength.

Ignoring Environmental Considerations

Neglecting environmental factors such as temperature, humidity, and ventilation can impact the performance of certain adhesives. It’s important to adhere to the recommended environmental conditions specified by the adhesive manufacturer for optimal bonding results.

Using the Wrong Type of Glue

Selecting the wrong type of glue for the specific materials and application is a common mistake that can result in ineffective bonding. It’s important to choose the most suitable adhesive based on the materials being bonded and the intended use.

By avoiding these common mistakes when using glues, individuals can optimize the bonding performance of different adhesives and achieve strong and durable bonds in their diverse projects, whether it’s woodworking, crafting, repairs, or DIY endeavors.

Conclusion

In conclusion, the proper selection and application of adhesives are crucial for achieving strong and durable bonds in a wide range of projects. Understanding the properties and ideal uses of different types of glues, such as wood glue, plastic glue, fabric glue, and all-purpose adhesives, is essential for making informed decisions and selecting the most appropriate adhesive for specific applications. Factors such as bonding strength, flexibility, weather resistance, and environmental considerations play a significant role in determining the suitability of an adhesive for a particular project.

Additionally, adhering to best practices for glue application, including proper surface preparation, even distribution of glue, appropriate clamping or pressure, and allowing adequate drying and curing time, can significantly enhance the bonding performance of adhesives. Conversely, avoiding common mistakes such as overuse of glue, uneven application, and rushing the drying or curing process is essential for optimizing the effectiveness of the adhesive and the quality of the bond.

By following these guidelines and understanding the specific properties and uses of different types of adhesives, individuals can confidently choose the most appropriate adhesive for their woodworking, crafting, repairs, DIY projects, and other applications. Whether it’s bonding wood, plastic, fabric, or materials for outdoor use, selecting the right adhesive and applying it properly can lead to successful and reliable bonding results.

In summary, the proper selection, application, and avoidance of common mistakes when using adhesives are essential for achieving optimal bonding performance and ensuring the success of diverse projects. By considering the specific requirements of the materials and applications, individuals can make informed decisions and effectively utilize adhesives to achieve strong, durable, and long-lasting bonds in their projects.

Frequently Asked Questions for Glues

What type of adhesive should I use for bonding wood materials?

For bonding wood, consider using wood glue (PVA), epoxy adhesives, or polyurethane adhesives, depending on the specific requirements of your woodworking project.

What adhesive is best for outdoor use?

For outdoor applications, consider using weatherproof adhesives, marine adhesives, or all-weather adhesives that offer resistance to moisture, UV radiation, and temperature fluctuations.

What type of glue is suitable for bonding plastic materials?

When bonding plastic, consider using cyanoacrylate (super glue), epoxy adhesives, or specialized plastic adhesives designed for specific types of plastics.

What adhesive should I use for fabric projects?

Fabric glue, spray adhesives, and hot melt glue are suitable for fabric projects, offering flexibility, washability, and strong bonds for various fabric materials.

What is the best adhesive for general household repairs and DIY projects?

All-purpose adhesives, including multi-surface adhesives and quick-drying all-purpose glues, are versatile options for general household repairs and DIY projects.

What type of adhesive is suitable for marine applications and boat repairs?

Marine-grade waterproof adhesives, such as marine epoxy adhesives and submersible adhesives, are designed for marine applications and boat repairs, offering resistance to saltwater and moisture.

What are the common mistakes to avoid when using glues?

Common mistakes to avoid include insufficient surface preparation, overuse of glue, uneven glue application, improper clamping or pressure, rushing the drying or curing process, ignoring environmental considerations, and using the wrong type of glue for the specific materials and application.

Super Glue Life Hack

Top Picks for Super Glue

Best Overall: Gorilla Super Glue Gel at Amazon

“Easy to use option that works with wood, metal, ceramic, rubber, leather, paper, and most plastics…gel consistency prevents messy runoff.”

Best for Plastic: Krazy Glue Maximum Bond Super Glue at Amazon

“A small tube is a great tool to have on hand in any home…can be used to fix a broken plastic toy as well as handle bigger and heavier issues.”

Best for Metal: Loctite Ultra Gel Control at Amazon

“Can bond quickly and without clamps after only about 5 to 10 seconds of holding…water resistant and not brittle.”

Best for Wood: Titebond Original Wood Glue at Amazon

“Polyvinyl acetate product…excellent with wood or porous materials.”

Best for Ceramic: Liquid Nails Small Project at Amazon

“Thinner or less viscous than some of the gel-glues on the market, perfect for filling those cracks and breaks in ceramics.”

Best Remover: Goof Off Super Glue Remover at Amazon

“Specially designed to get rid of the three popular super glue types: CA glues—like Super Glue—epoxy adhesives and Gorilla Glue.”

Best Budget Super Glue: Super Glue 12-Pack at Amazon

“Works best on nonporous materials like metal or pottery as opposed to wood or paper, but is broadly versatile.”

The Best Glue for Dollhouses

What are the different types of glue? See below.

The Chemistry of Super Glue

How does a super glue work? See below.